Safety is a top priority for Inxpect. To make workplaces safer, we have developed a sensor that prevents accidents through the use of the safest technology in the world: radar.

The LBK-S01 sensor creates an invisible barrier that detects when an operator crosses it and enters a dangerous area, putting the machine into a safe condition to protect the operator

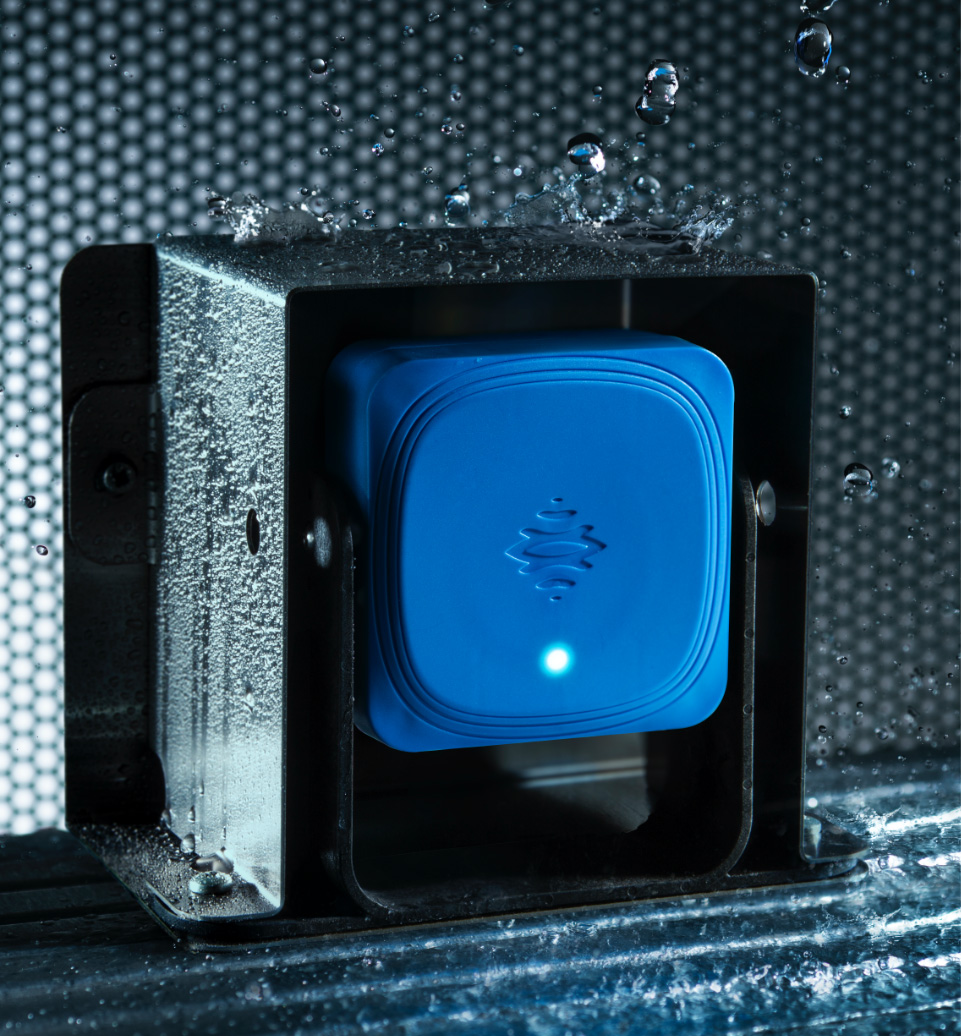

A radar sensor is extremely resistant to environmental disturbances. This makes it possible to work without false alarms in environments where there is smoke, dust, water and machining swarf

LBK sensors are the first (and the only one to date) radar sensors in the world that have obtained SIL2 certification for use in industrial safety applications. (Find out about the requirements necessary for this certification)

Radar functions natively in 3D, and can therefore protect dangerous areas volumetrically. Operators cannot elude detection by radar no matter how hard they try!

Inxpect radar systems adapt to many different usage situations in a wide range of working environments. Below are some of the most common usage scenarios, where radar technology has significantly increased safety levels in industrial environments.

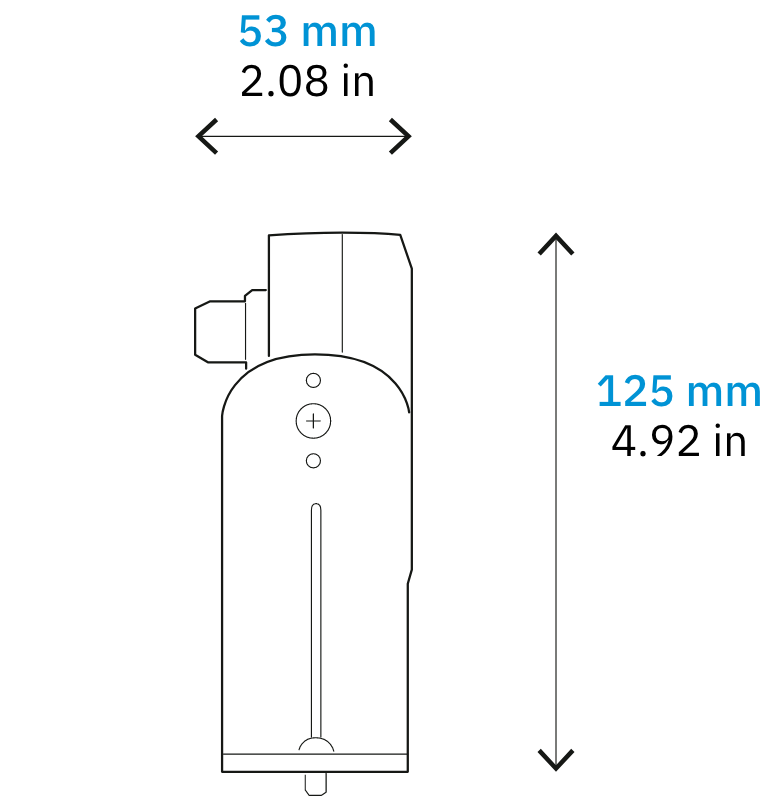

| LBK-S01 SENSOR | |

|---|---|

| Connectors | 2 5-pin M12 connectors (1 male and 1 female) |

| CAN bus termination resistance | 120 Ω (not supplied, to be installed with termination connector) |

| Power supply | 12 V dc ± 20%, through controller |

| Degree of protection | IP67 |

| Material | Sensor case: PA66 | Bracket: PA66 and glass fiber (GF) |

| Frequency |

Working band: 24–24,25 GHz (24.05-24.25 for UK and FR) Transmission power: ≤ 13 dBm – Modulation: FMCW |

|

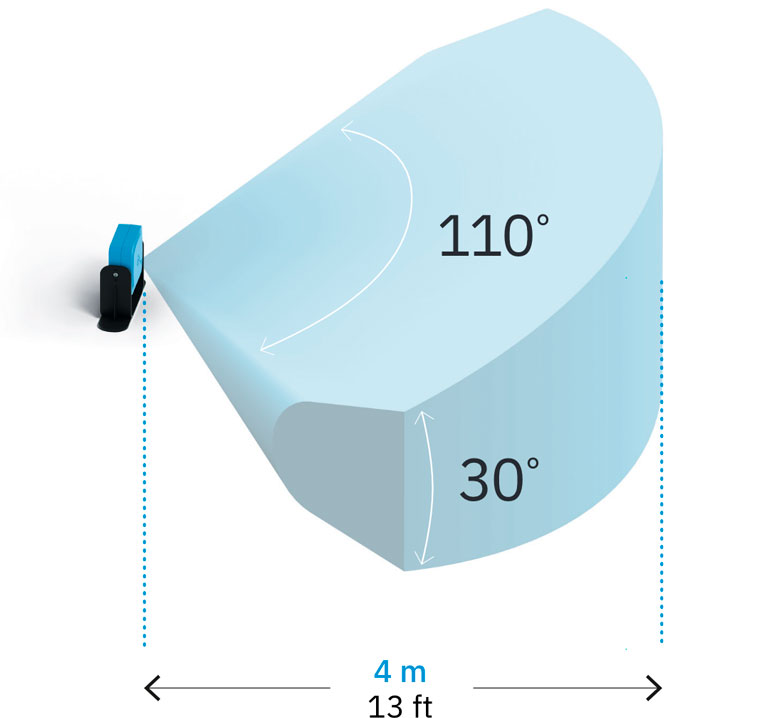

Sensing field and Installation height |

Wide FOV configuration: 110° Horiz. | 30° Vert., Height: 0 to 3 m (0 to 9.8 ft) Narrow FOV configuration: 50°Horiz. | 15° Vert., Height: 0 to 3 m (0 to 9.8 ft) |